Forklift and Attachment Data Rating Plates

We supply new Data Rating Plates for ALL Forklift Makes and Models.

We supply new Data Rating Plates for ALL Attachment Brands.

It is imperative that all forklifts are operated correctly and within their maximum limits.

In Australia, every fork truck must carry a rating plate that contains essential information concerning the safe use of the vehicle. Forklifts should never be operated without a rating plate, as the operator will have no indication of the capacity of the unit.

All the data appearing on the rating plate must be calculated by the manufacturer of the vehicle.

Damaged or illegible rating plates must be replaced and the plate must be visible to the operator from the operator’s compartment.

To ensure this occurs and to provide owners and operators with knowledge of these limits all forklifts under Australian standard AS2359.2 – 2013 must be fitted with a rating plate from the manufacturer that clearly defines the unit’s specifications.

This blog will explain how to read and understand the specifications on a rating plate for both combustion and battery electric models.

Combustion Engine Rating Plate

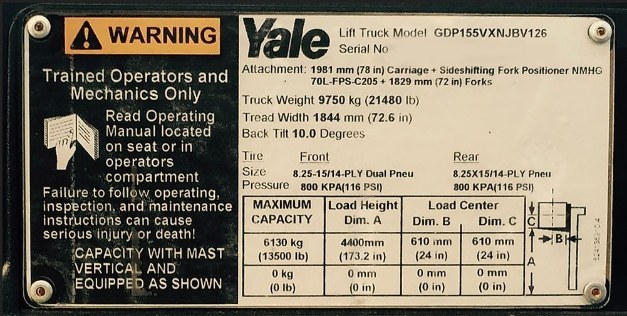

The top third of the plate as shown in the image above, details identifying specifications for the unit, including:

- Unit manufacturer

- Unit model

- Year of manufacture

- Unit serial number

Operators and fleet managers can use this information to identify a particular unit amongst a fleet or to track a unit’s service or parts history.

This information aids manufacturers in ensuring that the correct service and spare parts are provided for the particular unit.

1. Forklift Model

The forklift model the rating plate is attached to is clearly stated at the top of the plate.

The model of forklift is vitally important when communicating with the manufacturer or dealer regarding repairs, technical help and spare parts.

Being able to provide the forklift model when there is a fault technicians are able to look up the particular model to see if it is a common fault and how to fix it for the particular model.

Quoting the forklift model easily allows parts interpreters to select the correct parts that are specifically compatible with that model of forklift when supplying spare parts.

2. Forklift Serial Number

A forklifts serial number is also vitally important when communicating about repairs, technical help and spare parts.

It is a more precise way of finding out information on a specific forklift than a model number as they are unique to each unit.

Providing a technician or a parts interpreter with a unit’s serial number allows them to pull up the individual record of the forklift to see the unit’s precise setup and history, allowing them to match parts or troubleshoot known issues easily.

3. Year of Manufacture

States what year the forklift was manufactured.

Can assist in procuring the correct spare parts or troubleshooting known issues as units manufactured in specific years usually will share the same specifications or technicians know a specific model of forklift manufactured in a specific year are prone to a specific fault.

4. Nominal Power

States the nominal power (the average power consumed by the forklift) in kilowatts of the specific forklift.

5. Attachment

This lets owners and operators know if any attachments are fitted to the unit and what they are.

This gives a clear indication of the forklifts capabilities. In the example data plate above we see the Hyster 2.5T XT forklift is fitted with a side-shift carriage so the carriage and tynes can be shifted left and right of center as well as tynes that are 1,070mm long.

6. Truck Weight

Shows the forklifts overall weight without any load on the tynes.

The unladen weight of a forklift can be crucial for operators ensuring that any surfaces or areas they are planning on operating the forklift over are rated to specifically handle not only the full weight of the empty forklift but the weight of the forklift when it is carrying a full load weight.

7. Forward Back Tilt

Shows the specific number of degrees that the mast on the forklift can be tilted backwards and forwards.

8. Tyre Information

Details the specific size and type of that are fitted to the forklift.

This is helpful when ordering replacement tyres as all the information from the data plate can be relayed to a parts interpreter to ensure the correct tyres are ordered. When purchasing a new or used forklift the rating plate tyre data shows what is currently fitted to the forklift.

If the application the forklift is being purchased for requires a specific type of tyre such as non-marking tyres then buyers are able filter out any forklifts that do not have the correct tyre type via the information on the data plate.

9. Tyne and Mast Specifications

The load table that occupies the bottom half of the rating plate is critical for the safe operation of the forklift. The data in the table specifies important information regarding the forklifts load handling capabilities:

- Load Height is the maximum height the forklift mast can lift a load

- Maximum Capacity Mast Vertical is the maximum weight the forklift can lift when the mast is extended to its full height. The mast must be vertical and upright not tilted

- Maximum Capacity Mast Tilted Forwards is the maximum load weight the forklift can lift when its mast is titled forwards within the degree limit listed on the load plate

- Load Centre – is the balance point of the load where it is the most stable and secure, it is imperative to keep all loads central when lifting otherwise the risk of the forklift becoming unbalanced and tipping over greatly increases

10. Driver and Operator Warnings

Owners and operators are reminded that they need to be fully trained and hold the correct license to operate the forklift safely.

They need to read all the necessary manuals before commencing operations.

It is imperative that all forklift owners and operators familiarise themselves with a units rating plate, before they begin operations to ensure their own safety and those around them as well as property and equipment safety.

Damaged or unreadable rating plates must be replaced. It is imperative that all forklift operators familiarise themselves with a units rating plate, before they begin operations to ensure their own safety and those around them as well as property and equipment safety.